ARNA offers Wind Energy Optimization Solutions from Ventus Wind Services Gmbh, Austria by enabling wind farm owners to increase energy production and returns while driving down the risk and protection of assets by offering LiDAR based Services, Blade Pitch Misalignment Correction, etc.

Lidar Services

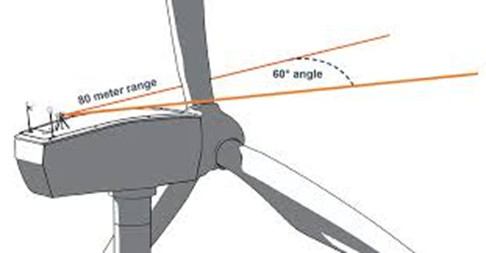

Using a nacelle-based LiDAR technology to measure wind speed and wind direction in front of the rotor and providing four main LiDAR services for turbine performance optimization:

- Yaw misalignment detection, correction & verification

- Turbulence intensity profile in 360° wind sectors

- Wind speed nacelle transfer function verification

- Power curve performance verification

Above services and analysis provides following benefits:

- Wind measurements from 80m up to 400m in front of the rotor

- Compare SCADA measurements with actual wind conditions

- Turbine specific nacelle transfer function

- Faster data collection for power curve measurement

- Increase in energy production

- Avoid premature wear and tear due to excessive stress and loads

- Prevent critical component failures and extend turbine lifetime

STATIC & DYNAMIC BLADE PITCH VERIFICATION

High resolution Camera & Ventus techniques are used to detect the Blade and Pitch angle. And the verification is done in following manner:

- Measure relative blade pitch misalignment from rotor in standing-still position to in full operation

- Measure relative difference in the blade aerodynamic efficiency

- Send measurement campaign summary to the customer including, report with results, conclusions and recommendations. All reports are accompanied by pictures and videos-captions

Following are the benefit of the same:

- Increase in energy production

- Avoid premature wear and tear due to excessive stress and loads

- Prevent critical component failures and extend turbine lifetime

- Measurement campaign conducted in few hours

- WTG is not stopped during dynamic blade pitch measurement

TripleCMAS™ – A SELF-POWERED ROTOR MONITORING SYSTEM

- Wind turbines are often subjected to extreme mechanical stresses. Condition Monitoring Systems ensure that mechanical failures are detected before they become a danger to the entire wind turbine operation.

- Ventus TripleCMAS™ (Critical Components Condition Monitoring fault detection and instant Alarm System) for the most efficient use of wind turbine data specifically designed for the wind turbine industry. Based on Artificial Intelligence and Machine Learning techniques, this solution converts the rotor and the entire swept area into a real-time monitoring system.

- TripleCMAS™ (Critical Components Condition Monitoring fault detection and instant Alarm System): designed and patented by Ventus is the next generation of rotor condition monitoring solution. The independent and flexible system converts the rotor and the entire swept area into a measuring instrument for all existing and future wind turbines. The multi-modular solution includes easy-to-use sensors that, used in conjunction with the LEDS™ (Lightning and Electrostatic Discharge System) product, becomes a self-sufficient powering monitoring system.

- TripleCMAS™ is designed and patented by Ventus is the next generation of rotor condition monitoring solution. The independent and flexible system converts the rotor and the entire swept area into a measuring instrument for all existing and future wind turbines. The multi-modular solution includes easy-to-use sensors that, used in conjunction with the LEDS™ product, becomes a self-sufficient powering monitoring system.

- The real-time dashboard enables wind turbine operators to detect real-time failures at an early stage and turn unforeseen breakdowns into planned maintenance allowing wind turbine owners to make significant maintenance savings and increase the efficiency of the asset.